BS EN 10219-1:2006 Cold formed welded structural hollow sections of fine grain steels

This part of this European Standard specifies the technical delivery conditions for cold formed welded structural hollow sections of circular, square or rectangular forms and applies to structural hollow sections formed cold without subsequent heat treatment

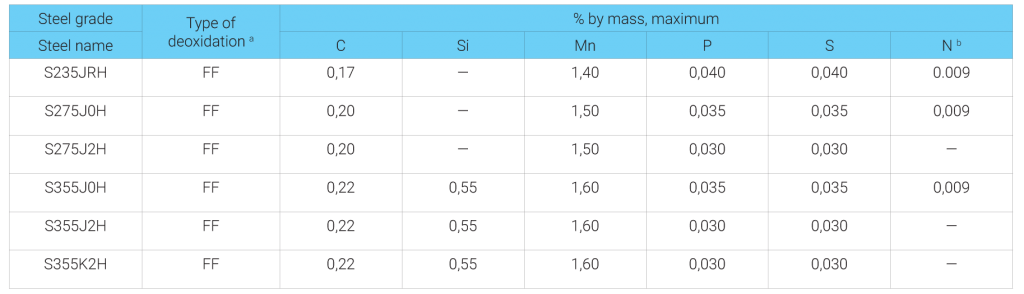

Chemical Requirement

Chemical composition — Cast analysis for product thickness ≤ 40 mm

(a) The deoxidation method is designated as follows:

FF: Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al or 0,015 % soluble Al).

(b) The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if suffi

cient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document.

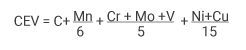

The maximum carbon equivalent value (CEV) for all grades, based on the cast analyses, given in Table A.2 shall apply. When determining the CEV the following formula shall be used.

Table A.2 — Maximum carbon equivalent value (CEV) based on cast analysis

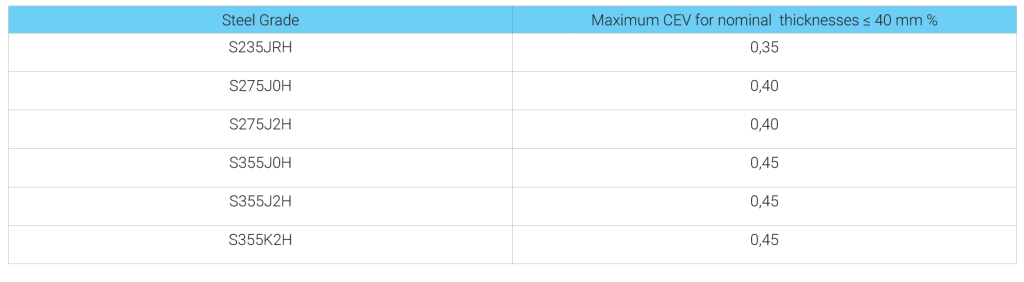

Table A.3 — Mechanical properties of non-alloy steel hollow sections in thicknesses ≤ 40 mm

- a The impact properties are verified only when Option 1.3 is specified.

- b For thicknesses > 3 mm and section sizes D/T < 15 (round) and (B+H)/2T < 12,5 (square and rectangular) the minimum elongation is reduced by 2. For thicknesses

≤ 3 mm the minimum value for elongation is 17 %. - c For section sizes D/T < 15 (circular) and (B+H)/2T < 12,5 (square and rectangular) the minimum elongation is reduced by 2.

- d For thicknesses < 3 mm

- e For impact properties for reduced section test pieces see 6.7.2.

- f This value corresponds to 27J at –30 °C

BS EN 10219-1:2006

Cold formed welded structural hollow sections of non-alloy steels – Tolerances

This part of EN 10219 specifies tolerances for cold formed welded circular, square and rectangular structural hollow sections, manufactured in wall thicknesses up to 40 mm, in the following size ranges:

- Circular: Outside diameters up to 2 500 mm

- Square: Outside dimensions up to 500 mm x 500 mm

- Rectangular: Outside dimensions up to 500 mm x 300 mm

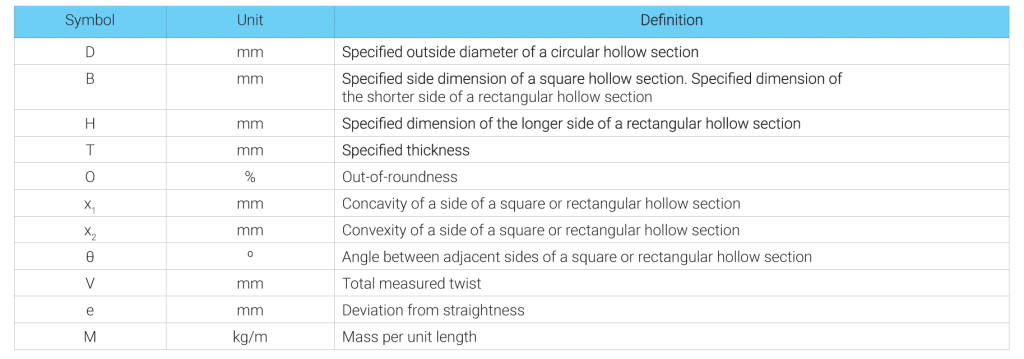

Symbols and definitions

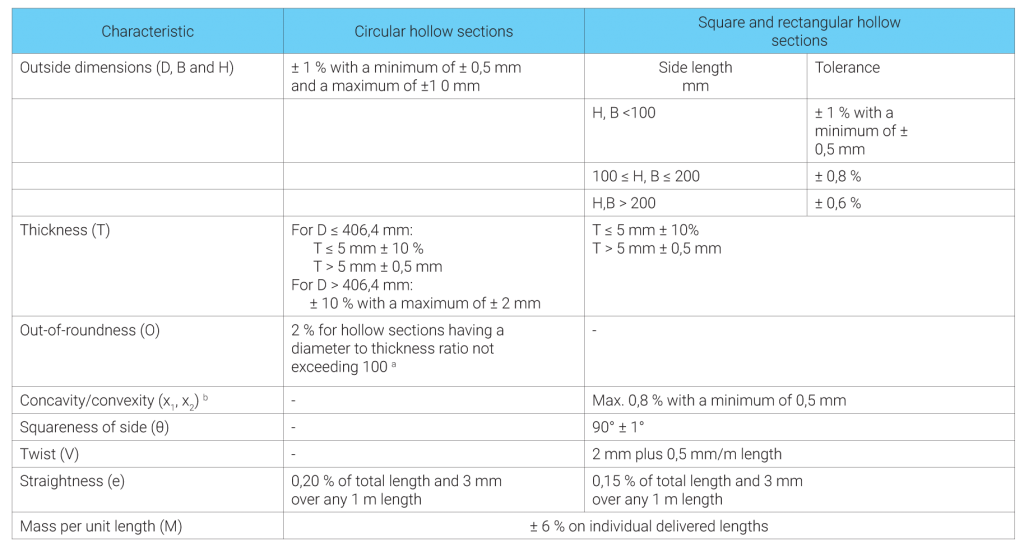

Table 1 — Tolerances on shape and mass

a Where the diameter to thickness ratio exceeds 100 the tolerance on out-of-roundness shall be agreed.

b The tolerance on convexity and concavity is independent of the tolerance on outside dimensions.

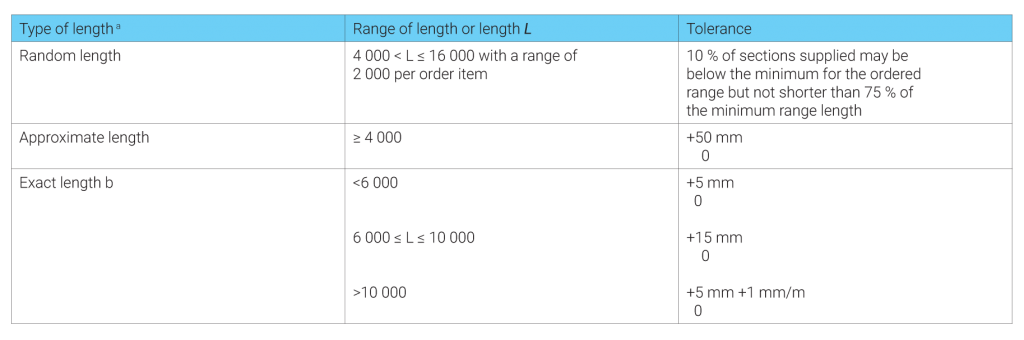

Tolerances on manufacturer’s delivered length

a Where the diameter to thickness ratio exceeds 100 the tolerance on out-of-roundness shall be agreed.

b The tolerance on convexity and concavity is independent of the tolerance on outside dimensions.