API 5L : Specification for Line Pipe

PURPOSE AND COVERAGE

The purpose of this specification is to provide standards for pipe suitable for use in conveying gas, water, and oil in both the oil and natural gas industries. This specification covers seamless and welded steel line pipe. It includes plain-end, threaded-end, and belled-end pipe, as well as through-the-ftowline (TFL) pipe and pipe with ends prepared for use with special couplings.

Although the plain-end line pipe meeting this specification is primarily intended for field makeup by circumferential welding, the manufacturer will not assume responsibility for field welding.

GRADES

The grades (see the note) covered by this specification are the standard Grades A25, A, B, X42, X46, X52, X56, X60, X65, X70 and X80; and any intermediate grades (grades that are higher than X42, intermediate to two sequential standard grades, and agreed upon by the purchaser and manufacturer). PSL I pipe can be supplied in Grades A25 through X70. PSL 2 pipe can be supplied in Grades B through X80. Class II (CI II) steel is rephosphorized and probably has better threading properties than Class I (CI l). Because Class II (CI II) has higher phosphorus content than Class I (CI l), it may be somewhat more difficult to bend. Pipe manufactured as Grade X60 or higher shall not be

substituted for pipe ordered as Grade X52 or lower without purchaser approval.

Note: The grade designations are dimensionless. Grades A and B do not include reference to the specified minimum yield strength; however, other grade designations are composed of the letter A or X, followed by the first two digits of the specified minimum yield strength in U.S. Customary units.

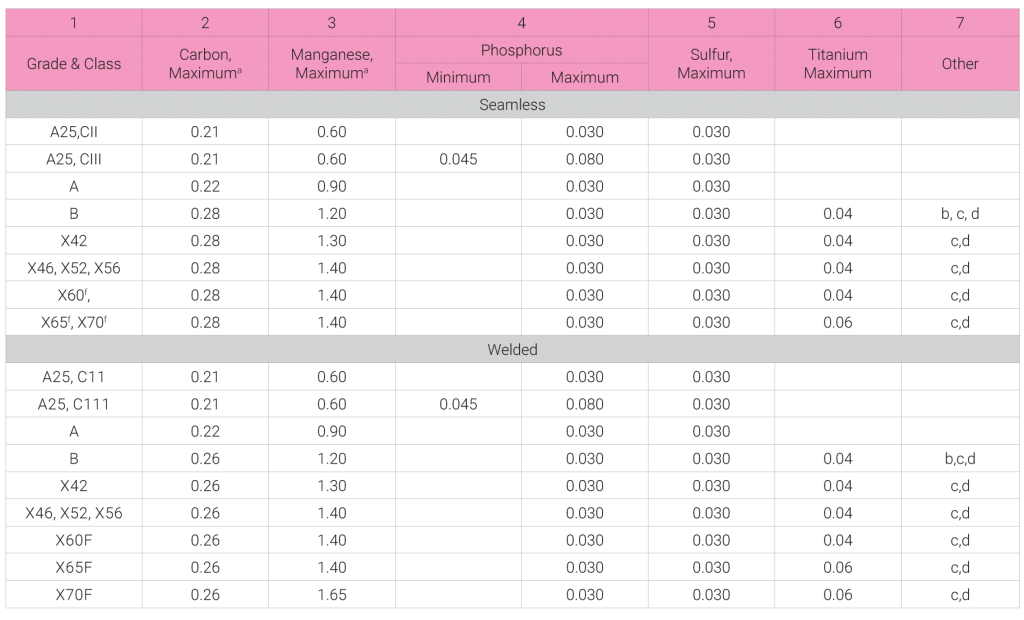

API SPECIFICATION 5L Table 2A-PSL 1 Chemical Requirements for Heat and Product Analyses by Percentage of Weight

Chemical composition — Cast analysis for product thickness ≤ 40 mm

A The total composition for these five elements shall not exceed 1.00 %.

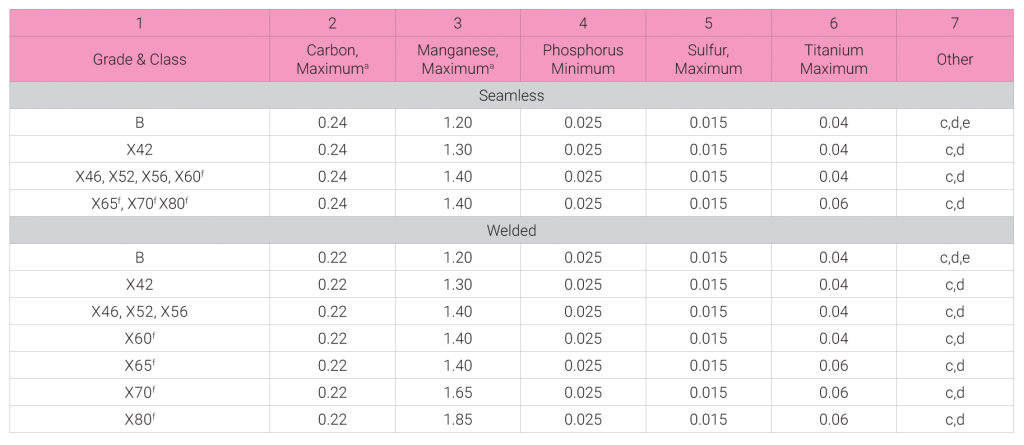

API SPECIFICATION 5L Table 2B-PSL 2 Chemical Requirements for Heat and Product Analyses by Percentage of Weight

Footnotes to Tables 2A and 2B:

a For each reduction of 0.0 I % below the specified maximum carbon content, an increase of 0.05% above the specified maximum manganese content is permissible, up to a maxi

mum of 1.50% for Grades X42 through X52, up to a maximum of 1.65% for grades higher than X52 but less than X70, and up to 2.00% for Grades X70 and higher.

b The sum of columbium Iniobiuml and vanadium contents shall not exceed 0.03%, except that, by agreement between the purchaser and the manufacturer, an alternative maxi mum may be established.

c Columbium [ niobium], vanadium, or combinations thereof may be used at the discretion of the manufacturer.

d The sum of the columbium [niobium], vanadium, and titanium contents shall not exceed 0.15%.

e The sum of the columbium [niobium], and vanadium contents shall not exceed 0.06% except that, by agreement between the purchaser and the manufacturer, an alternative

maximum may be established.

f Other chemical compositions may be furnished by agreement between purchaser and manufacturer, providing that the limits of footnote d, and the tabular Iimits for phosphorus

and sulfur are met.

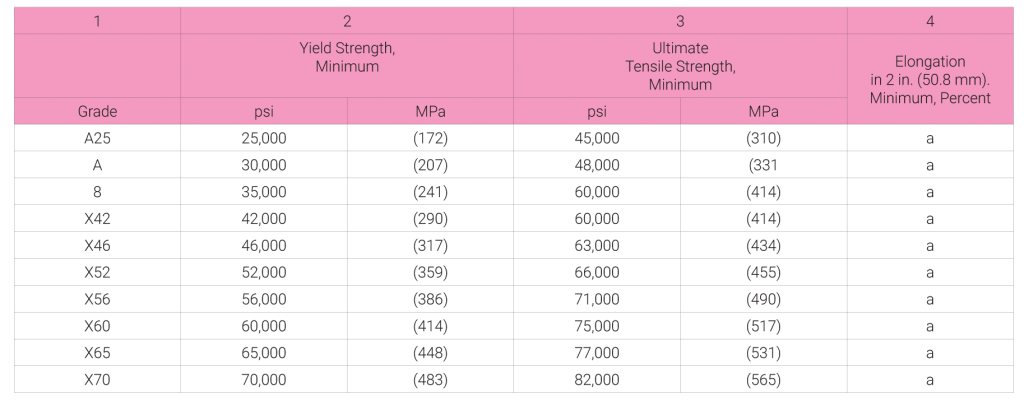

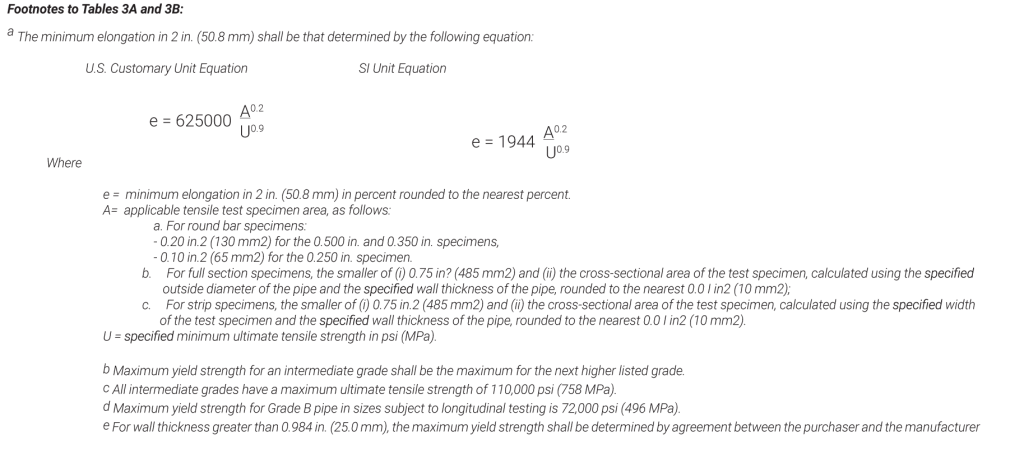

API SPECIFICATION 5L

Table 3A-Tensile Requirements for PSL 1

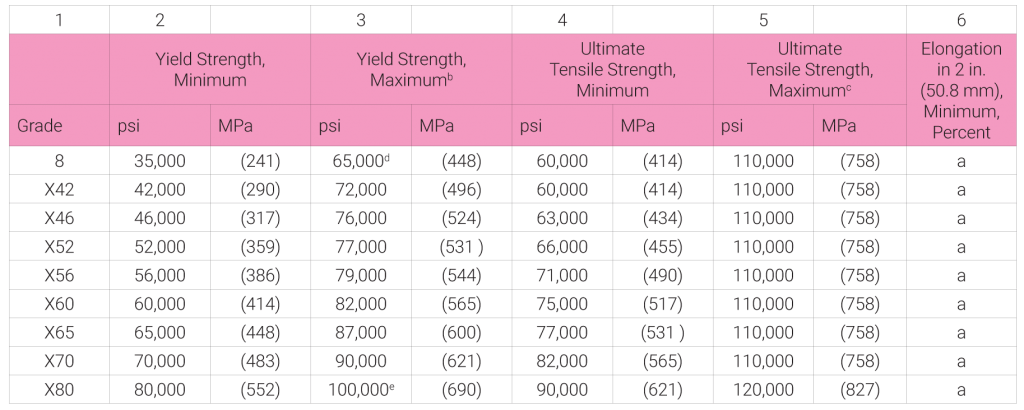

API SPECIFICATION 5L Table 3B-Tensile Requirements for PSL 2

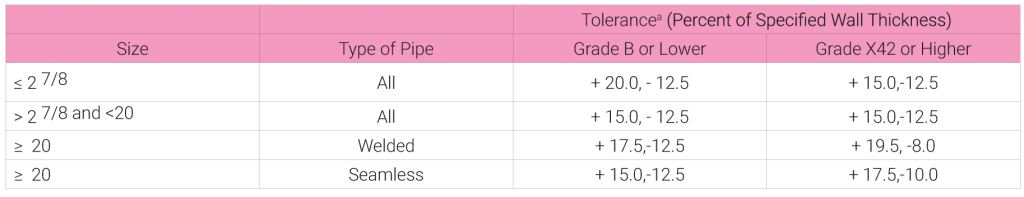

a Where negative tolerances smaller than those listed are specified by the purchaser, the positive tolerance shall be increased to the applicable total tolerance range in percent less the wall thickness negative tolerance.